Translate This Page

Before you buy a Citroen H van you need to be aware that parts are hideously expensive, for example Citroen Picasso front Calipers cost £61, the H van eqivalent are 400euros!!!

We don't sell H vans so this advice is impartial.

The difference in restoration costs between buying and running a 1961 van and a 1967 van is thousands as there were so many important changes. You will read on other websites, generally from those with a vested interest, that the vans did not change much during the production run from 1949 to 1981. They may not have looked like they changed much, but they did, a lot, as you will read later.

As a Catering Vehicle, a 1967 van will be literally twice as good as a 1961. Reliability on a pre 1962 van will be much poorer, the Old fashion 1930's style 'Open' Colling system is a major factor here. The post 1967 van is also much nicer to drive. Much, much better Brakes (they actually work well if restored correctly), better fuel economy, more reliable by a huge margin, lights that allow you to see where you are going, a better Gearbox, stronger cheaper to rebuild Driveshatfs, etc

See more below :

Picasso H Van

Brake Pads/Shoes (front) £25 £120

Brake calipers/Cylinders (fr) £61 400€

Water pump £49 £249

Starter Motor £89 350€ (and the original Inertia Starters only had a short life)

Alternator £79 220€

Clutch £69 £470 (full kit = Release Bearing £120, plate £89, cover £260).

Distributer £0 £290

Total £372 £1,919

The H van is very time consuming to restore if the bodywork is poor. Likewise very time consuming to paint because of all the difficult contours. There are few flat surfaces so preparation and rubbing down time can be twice a typical vehicle.

They can cost twice as much to paint as say a VW Camper.

Front Nose panels (the bit the headlight is bolted to) are 600€ the pair to buy with around a days fitting on top + paint.

So clearly one that needs both bodywork and mechanical work is going to cost a lot of money to get smart and reliable. No wonder one Classic Car TV Show recently said they can be a Money Pit.

So many people have been caught out by the enormous cost of everything. Little things like Window rubbers can be £100 a set, seats that cost £100 a cover + around £50 for the rubber 'springs', etc. There are usually so many small things that will require replacement on a 40 year old van that even if the cost of each item was small (which it isn't) it would still be a lot of money. Many people also think they can use parts from a different model, only to find these vans are so unique, very little else will fit. What is interchangeable, like a brake light switch, is usually the low cost stuff.

Do your homework and carefully calculate how much each little tiny item will cost to put right.

Citroen H van Advert Translation.

That van in the advert that sys, "just needs a little TLC", should be interpreted as 'allow at least £5,000 to get it half way decent'.

An advert that says 'Just needs an Engine service' translates to 'the engine is 50 years old, of course it's going to need a full rebuild'.

A modern car tells you if something is up. If the engine starts and runs nicely, it is probably good.

An H van engine will start and run even in poor condition. Then without warning blow the Cylinder liner lower gaskets (often incorrectly diagnosed as Head Gasket failure). This is not because of a weakness in the engine, the engines are very strong and reliable, but a gasket has a 20 year design life, it will not like being asked to go to work every day after having a gentle slumber for the last 30 years.

The other favouite failure is a Conrod through the sump. The engine Block/Sump damage below was from a van that came into the workshop in November 2015 and was the fifth one we had seen that year. This type of damage is usually caused by use of a modern Oil.

The owner of this engine, Stewart, was told by his Garage that modern Oil was better than the correct Vintage SAE 30 Oil.

As you can see from the extensive damage caused, his Garage certainly know all about Classic vehicles!!!

Buying the van from a 'big Dealer' won't guarantee you don't get major bills, unless they offer a very comprehensive Warranty.

Which year, model to buy?

If you are buying the van for use as a Classic occasional use vehicle where the mileage will be limited, the early ones with the split screen are more cute.

If you are buying the van for use as a Catering project then avoid the early pre 1963 vans as these can be the most expensive to both restore and keep on the road.

You will read elsewhere that the van changed little during it's production run? This is not true, there were literally hundreds of changes, almost every one an improvement.

The early H van up to 1962 really isn't suitable as a Catering vehicle. The Cooling system is an 'open' system prone to overheating if asked to haul a heavy van. The engine was just 35bhp, the Brakes poor, the Gearbox weaker, the Driveshafts prone to wear, the wiring sheathed in a kind of Cotton wrap that rots (not rubber or plastic), a poor handbrake, a 6v electrical system which is dreadful at lighting up the road. The 6v dynamo will take a month of Sundays to recharge a battery, etc.

Everything about the early vans makes them ok for use as an occasional Classic, but a later van from 1963 on will be more usable and cheaper to restore and run as a Catering truck. For example an Early H van can cost up to £2,000 JUST to rewire and convert to 12v.

By the late 1950's Citroen realised the H van was seriously lagging behind rivals, so a major improvement plan was begun.

It got a new Engine in 1963.

The post 1963 vans also got 12v electrics, with real Indicators and Headlights that were much improved. Alternators were introduced so the battery nearly got fully charged up. Carburettors improved. Engine mountings also changed. The Air filter was twice as efficient and half the cost to renew the Element.

The 'Hockey stick' handbrake, that was often accidentally kicked off by mistake allowing the vehicle to roll down an incline, was changed for a more conventional, safer, lever and rachet lock arrangement. This was safer on two aspects because it was now impossible to nudge the hand brake off, but it also operated on the front wheels, not the rear wheels as previously. This helped with emergency braking as the front brakes had more stopping power.

The new 1,911cc engine design in 1963 was a big leap forward. Every thing was improved from the fuel economy, power and top speed. Power increased from a paltry 35bhp in 1947 to 55bhp in 1963. It was still poor, so don't expect even the later van to accelerate faster than a Snail. To give you an idea of how poor, a 1959 Austin Mini 850cc car had 42 bhp, the 1,911cc H van early engine was twice the size yet had just 35bhp.

The Wiring Loom changed from being a Rat/Mouse delicacy of Cotton wrap, to a modern plastic coated copper Wire. Rare to find a pre 1961 van that doesn't need major wiring surgery, with a Dash wiring loom at 300euros (part loom only) and lots of time to fit, it works out a major expense.

Around this time the brakes were uprated several times on the rear along with bigger, wider drums on the front. The post 1963 brakes are quite good.

The Torsion Bar size was improved raising the load capacity and improving the ride. The Torsion Bar 'Bearing' also improved.

Wipers got an automatic park facility. Up to this time the wipers would stop where ever you cut the power, usually hampering your vision. The trick was to time the point at which you turned them off. Usually resulting in reduced road awareness as your eyes followed the wipers.

The exhaust was changed so the smelly fumes were taken further towards the rear of the van, not back in through the Drivers open window. Rear wings changed.

Around 1968 the rear brakes were again uprated with the amount of force on the back wheels being dependent on the load carried. The greater the cargo load, the more the stopping power. Up until this time the rear brake effort was either too poor when the van was loaded or too severe when it was empty such that they locked up and the van went sliding sideways down a wet road. These vans built after 1968 actually have very good Brakes. Literally more than twice as good as a 1961 vehicle that had narrow front drums and small rear brake Slave Cylinders.

The front subframe improved again, this time dropping the 4 front Shock Absorbers with a move to just 2, more powerful. units. A set of front shocks for an early van can cost over £360.

Cab Doors changed and got decent 'anti burst open' safety catches to reduce the risk of the door flying open as you drive.

Windows locking properly.

A heater also became a standard fit item.

There are 3 Seat variations. Unusually, the early ones are the most comfortable.

The rear upper door window increased in size so you could almost see out of it.

Seat belts were sometimes fitted.

Mirrors improved.

A modern brake stop light switch was adopted.

It goes on.....

1963 was a real landmark in H van production, the vans prior to this time really are very, very different to restore and run.

The second major revamp was in 1967 when the van gained a stronger Gearbox, possibly in preparation for the forthcoming Indenor Diesel engines. Banished at the same time were the awful sliding joint Drive shafts and the poor syncromesh on second and third. The gearbox was stronger and the syncromesh easier to overhaul.

Driveshafts are also much stronger and capable of a rebuild unlike the early ones. Later gearboxes tend to have higher ratios than an early box. Clutch design was also a big improvement, especially for heavily loaded vans.

The Gearbox does not look it when you peep inside a late versus old box, but almost every key componenet was changed/improved in some way. Few components are interchangeable between the early and the late box.

Really a shame the redesign didn't go far enough by adding syncromesh to first and a 4th Gear.

When an Early Gearbox gets tired, it is usually beyond economic rebuild. The later, post 1967 box is usually capable of a rebuid.

All the above mean a post 1963, or better still a post 1967, is a much stronger van with MUCH lower restoration and running costs. For example 2 handbrake cables for an early van will cost around 180 euros versus the later vans 60 euros.

An early engine rebuild, with it's white metal Conrods can cost an EXTRA £400 to the engine rebuild cost, just for the white metal machining, if you can get find someone who still has the art?

If an early Gearbox breaks you usually have to resort to sourcing a good second hand one and they are very rare in good condition, at best the syncromesh is shot.

If a good second hand Box is not available, a good late version gearbox PLUS driveshafts needs to be sourced, this can result in the bill for an early gearbox failure being twice that of a later van. Don't expect much change out of £3,000.

But even if you ignore all the above, common sense says that a van that is 'only' 40 years old is going to be a more reliable proposition than one that is 67 years old. As far as appeal goes, your average customer won't know the difference between a late 4 vent bonnet (for the Heater) and an early 2 vent.

Buy the youngest van you can. For a heavy Catering van or one that is longer or higher, choose a post 1971. Leave the early pre 1963 vans to the collectors to put in a Museum.

Which Model/Version.

The Citroen H van was built in only a handful of models by the factory, like the standard van, the Pickup, etc but Citroen provided very good support to a large number of Coach builders who then went on to construct all manner of variations from Cherry Pickers, Beast carriers and Long Market vans.

Amongst the most valuable are the Long Wheel Base (LWB) vans where the body was stretched between the wheels. Next up are the extended vans which usually had the body extended to the rear of the back wheels. This varied from 250mm to 1,000mm. Sometimes these longer vans also had a higher roof.

Very rare are the vans with both a LWB and a rear extension. They also tended to have a raised roof. These are also the most fragile due to the greater tendancy to carry high loads and the extra length placing a bigger strain on the structure. Carefully check these vans for structural integrity, especially if someone has cut big side openings for a Catering hatch without extra additional bracing which will weaken it further. See the Gallery page for pictures on how to spot the different versions.

Now that you have bought one, what about getting it Restored?

A good H van Restoration cost has a very high labour content, therefore the costs to the restoration company doing the work build slowly over time. Any company that asks for 70% up front payment is ripping you off.

Yes parts can be expensive, but these are bought as and when that part of the van is attended to.

Therefore most good restorers will ask for stage payments to keep up with their costs, usually no more than about £2,000 a time. There may be the odd exception, like when acquiring an Engine or Gearbox, when the stage payment will be higher, but that is not the norm.

Make sure you know in advance what you need to pay and when. Inspect the work regularly to ensure what you are being billed for is being carried out.

Catering Conversion

The same applies to having a restored H van converted into a Catering truck. There are some expensive appliances, but they are normally only fitted near the end of the Installation, so should not be billed in advance of that.

An H van has an engine that can be 35bhp, that is less powerful than a 1959 Mini 850cc Saloon cars 42bhp, and that only carried 2 passengers, all in about 1200kg with luggage. You can probably imagine how a 1400kg H van engine copes with a 1500kg Catering fit-out + stock when it is already slower than a Snail?

That weight will make it harder to go up hills, increase fuel consumption, strain the Engine, Gearbox, Clutch, etc.

Any weight you add at the Catering Conversion stage should be the absolute minimum. If your Catering converter does not talk about light weight materials and minimalist interior then he is probably used to fitting out modern vans with 200bhp Turbo Diesel engines with a real Clutch? Either that or he builds big steel trailers that are towed by huge 4 x 4's?

If he starts telling you that Stainless Steel is light, try picking up an 8' x 4' sheet to see just how light it is? Steel is heavy, fact.

The best H van Catering conversions we have seen have been by Camper Van Builders.

Their Bread and Butter every day work is cramming in a Kitchen, a Lounge, a Bedroom and a bathroom. They know about maximising every tiny space and light weight.

A small Motorhome has an Oven, worktops, hygenic wipe down surfaces, Grill, Burners, Sinks and Fridge, usually in a space a quarter of that in a Steel trailer. It also has a Shower, bedroom, etc

Don't assume that a Catering Trailer builder is the only option for an H van. All a Coffee/Pizza H van needs is a kitchen.

Consider that House style Kitchen units are very, very heavy.

What are they like to drive?

Wonderful, and Awful.

You will get a lot of attention and looks. Everyone will love it.

On the downside they are so noisy you need ear plugs. The Steering is so heavy you will won't need to go to the Gym any more.

They are slow and the running costs will drive you mad. When you go anywhere, allow an extra day, especially if it's raining as the Windscreen Wipers and de-mist system are not and don't.

Learn to relax about the 5 mile traffic queue behind you, they will understand. Probably.

Oh and they don't have a Heater. Even the later versions after 1963 that have a Heater, don't have a Heater.

General

Check it has been notified to HMRC via the Notification Of Vehicle Arrivals system as you may be liable for the £5 a day late charge of notification, see the page on Importing and Registering a Vehicle. This is especially important if was imported pre NOVA (April 2013) and not yet registered as the NOVA late fee could be thousands.

Your choice of vehicle might be relevant to where you want to use it, for example if you intend to operate in/around London you should look for a Petrol engined van (any year) as this is classified as a Car for the purposes of the 'Zone'. If you specifically want a Diesel engined van only those registered before 1/1/1973 are classified as a Historic vehicle and exemption from the LEZ.

Diesel engine H vans registered after 1/1/1973 will be subject to the punitive £100 a day LEZ charge. If you already have a Diesel van registered after 1972 then you can get around the LEZ by converting to Gas or fitting approved filters.

If you intend to travel long distances avoid the Heavy Beast carriers as the extra height has a big impact on the Top Speed meaning some will struggle beyond 45mph. The greater weight will also affect top speed and fuel economy. The best long distance vans (if there is such a thing) are the post 1967 Petrol Standard vans with the absolute minimum weight.

We are getting vans recovered into the workshop with serious mechanical issues. In one instance the van had been delivered by one of the biggest H van restorers in the UK only 5 weeks previously, yet the engine failed catastrophically with a Conrod through the block. A failure so big the Engine was unrepairable.

The van looked fantastic, but only the minimum mechanical work had been done to get it through an MOT, despite the the Invoice saying, "it's had a thorough mechanical overhaul". The van cost almost £20,000. The Catering Installation was well over ANOTHER £18,000 on top. So this wasn't a van restored by Tommy Smith in his shed.

Despite it's "thorough mechanical overhaul" there was no Warranty for this work.

A properly restored van should give few issues.

Before you buy a van, especially if it is from a 'Professional' Restorer, have it independently checked by someone who understands Classic Vehicles and especially H vans. This vehicle Inspection Company : http://www.alternative-vehicle-inspections.co.uk/ (07980-619595 ) does not charge the earth and will give you a £10 discount if you mention us.

These guys above gave us a quote less than half the price of an equivalent RAC inspection but are South East Based : Kent, Sussex, Surrey, Essex, London, Suffolk, Bedford, etc.

If you are outside their area then try Carinspections.co.uk, 01780 749449, who will provide Inspections UK wide including Northern Ireland. Again if you mention us you will get a £10 discount.

These two companies can save you thousands, unlike the RAC and AA vehicle inspection team, they have specialist Classic vehicle Inspectors.

They might even be able to help you make a Claim where you have already made an unsatisfactory purchase by producing an expert written report about the vehicle condition to take to Court. Remember when you buy an H van that has been professionally restored or converted, it must be fit for purpose.

When buying an H van don't underestimate the cost of getting it reliable. Time and again we hear stories of a van bought that looked like new (sadly only with a pretty coat of paint and little other work) but within a short space of time the bills for thousands then roll in. See Famous Hy's page and the Sarah Cox item for an example story.

Joanne Adams, has a similar story, pretty looking 'new' van, but £2,200 was spent within months and the bills are still coming in.

The H van is strong but it is not magical.

If there isn't a Warranty, there will be a very good reason why.

Getting your your van inspected prior to purchase, will be the best investment you ever make, just ask anyone who has bought a 'restored' van.

In the photo below you can see the Black plate listing the vehicle model, such as HY72 and the weights. These weights are important for registering the vehicle, see our HY Dimensions Page for more info what the figures on the plate mean.

Then behind the Engine cover you can see the Red plate. If these are not present we suggest you buy the vehicle only for Spares. For help on how to registering an import H Van, CLICK HERE.

It is very important to be extra vigilant where the vehicle has already been 'restored' because all manner of horrors are easily hidden.

If the van is not prepared properly it will deteriorate very quickly returning to its pre-restoration state in a very short time. The structural integrity may also be compromised.

The Picture below shows some of the common rust areas, on the Nose Cone behind the Headlight, the step, above the step and along the curved panel above the wheel arching. Plus the triangular piece just behind the wheel arch.

It is not hard to make the Nose Cone 'Pig Snout' look good but each side panel that the Headlight sits on will cost about 300euros just to buy the panel then about half a day to fit.

That is why some of the budget restorations weld in flat repair panels, see below.

Our advice would be that if you see the above bodge ( note the missing flutes behind the Headlight where they have just welded in a flat panel rather than replace it properly?) expect every other part of the restoration to be the same underneath that paint and walk away. If they cut corners on such a key cosmetic that is so visible, what will the hidden bits be like?

Everyone else who views the Van will also know it's been bodged, not just the Nose but most likely the entire van, so if you ever need to sell it at a later date it will be worth a lot, lot less.

Below is how the Nose Cone should look, so much better with the flutes all the way down the Nose.

If you want to buy the Nose Cone panels, there are 3 different versions so do your home work before you order them.

The vans will and do rust, so expect some bodywork damage and get an estimate of the cost to put it right before you buy.

Where one body panel meets another is where they rust, as condensation gets in between the metal.

Very little is difficult to sort out, but it is time consuming. If you restore one yourself, we suggest you take lots of photos to show the next buyer what was bad and how it was fixed properly. It adds a LOT of value to the vehicle.

The cost of putting a bad restoration right can be thousands, so only buy a restored vehicle if it has a photographic, documented history.

BODY AND CHASSIS

Although I refer to the chassis separately the Van is in fact unitary construction. The Chassis is not a separate piece with the body bolted on top as most Commercials of the era. Therefore the strength of the body contributes to the overall integrity of the van so it is vital this is repaired properly, if rusty.

The floor is double skinned with a flat sheet on top and a corrugated piece welded beneath, visualise corrugated card board. It gave a relatively light weight floor that was strong enough to take a Horse, this along with the low height of the floor made it an ideal Horse box and many of this type were built as Betailliere, or beast carrier.

However, condensation gets between the 2 layers of steel and it rusts from the inside out. Look out for paper thin steel in the lower corrugation, even when the top floor layer looks good.

This photo shows the floor construction with rusted, paper thin, metal.

Compare the above mid right paper thin section with this good piece :

Look for tell tale signs of indentations in the top floor layer, especially if you can see 'hollows' down the length of the vehicle. This is a sign of a paper thin floor. If the top floor layer is poor, anticipate the bottom layer will be worse and if the steel is thin it should be replaced. Once the bottom layer perforates with the tiniest pin hole it lets in more water and road salt leading to failure inside months. If the original floor is covered by a wooden floor be extra cautious.

Someone once said to me that his vehicle had lasted 50 years and will last another 50. It might, but remember a H van in the UK has a much tougher life than 'at home'.

In France, during the vans 50 year life there will have been almost no salt spread on the French roads, the climate is not as harsh and the Winter shorter. An H van floor in less than perfect condition, with less than perfect protection, will not last one Winter in the UK.

Don't underestimate the role the floor takes in the strength of the vehicle, it is the main element of the structure to prevent twist and distortion. It does not just take the weight of the cargo, it pulls together all of the upper body.

Because it is a key part of the vans strength it should fail an MOT if it is poor.

When you are viewing a van to buy check under the vehicle very carefully, you will see two big chassis members running from front to back. Check these for damage. These are vital parts of the structure, carrying the mountings for the rear axle. They are particularly important in the longer vans and Pickups.

Although they look like big strong metal sections they are little more than 1 mm thick steel, and get deformed very easily by people (often Garages) trying to use them as a jacking point to raise the vehicle. On other vehicles of the era these chassis sections would usually be very thick steel that will take a lot of weight. NEVER try and raise the vehicle by these 'beams' and make sure that any garage that does any work understands the chassis. Likewise the 'Jacking point' is not designed for a trolley Jack which will crush them. They are designed purely for the Spare Wheel Jack that spreads the load via it's long arm that is inserted into the tube.

Also inspect the big box section 'Ring' structure that runs around behind the cab in a big circle. Everything hangs off this 'ring', Engine, suspension, front body section/Cab and the whole rear end. It is crucial that this 'ring' of square, box section steel (which is mostly only very thin 1 mm) is in absolutely perfect condition. It rots at the bottom centre and on the lower section to the rear of the doors. It corrodes from the inside out, so what initially looks like good steel, might just be a coat of paint. On the Horse boxes, this 'Ring' rots badly at the bottom centre of the ring at the junction of the rear floor. Animal urine is very corrosive. Every Beast carrier we have seen has had a rotten floor beneath the the thin layer of steel often welded on top to hide how bad it is.

RUNNING COSTS:

These vans are from an age when servicing every 3,000km/1,800miles was a long service interval. These vans rarely covered more than 6,000 miles a year.

At about 3,000km the Brakes will start to degrade, the Distributor will cause misfiring, poor running and higher fuel consumption. The Oil will be at the end of it's life.

The tappets need adjusting every 10,000km when the Chassis also needs Greasing. The Distributor does not even have the 'Oiling' pad fitted to later 1970's Cars so the Points deteriorate and the timing goes out within a hundred miles of being set-up.

The chassis points require regular Greasing, or you will get big repair bills.

Old vehicles were very high maintenance with a lot of labour involved, so budget for regular major services costing around £250 - £750 every 3,000km/1800miles.

ENGINE :

The Petrol engines do not have an Oil Filter, so it is vital that the Oil is changed every 3000km with the correct Vintage low Detergent Oil. You must not use a modern Oil, like a 10/40, as they contain detergents which are designed to clean all the sludge and rubbish from the sump and carry it to the Oil Filter. Because these engines don't have an Oil filter, all of the garbage picked up from around the engine gets carried over and over through the Bearings, wrecking them. A Vintage Oil is designed to drop any contaminents into the sump where it gets flushed out on an Oil change.

The 3 Diesel engines are unbelievably slow, the early ones struggling to reach 45mph. They are only slightly more fuel efficient than a Petrol engine as Diesel engines of the sixties only managed a few more miles to the Gallon. The main attraction in the 1960's being 19% lower cost per gallon at the fuel pump. These days with Diesel costing more per Gallon, a Petrol van will probably have lower running costs.

Even in the very latest version the Diesels are slow, smelly, noisey, much less powerful than the Petrol.

You are probably used to modern Diesel engines having more Torque than a bigger equivalent Petrol engine, yet back in the seventies the H van 1,600cc Petrol had more torque than the 1.9 diesel. A Diesel engine rebuild is not cheap.

That Blue smoke haze that follows a Diesel van is normal, don't worry about it.

Did I tell you about the noise inside a Diesel H van cab where the engine is next to you underneath a flimsy metal cover and a removable floor with gaps every where? It is unbelievably noisy. I SAID IT IS REALLY NOISY.

NO, NOT DID YOU BUY IT FROM BOISSEY, I SAID...

Be very cautious about buying a Diesel van if it is a non runner. If the Diesel engine is good they will cover hundreds of thousands of miles. 200.000 miles is typical, probably one of the strongest, most reliable engines every made. It is tha same engine as used in the Peugeot 504, and as a reputation that is legendary for being tough.

However, if it is bad, it may cost thousands to put right.

If the owner says, "just needs a service and a new battery......", you know what to do.

If you want 38MPG ecomomy, buy a Petrol and pay £900 having it converted to LPG. It will be cleaner, more economical and quieter.

The design of the H van floor and engine hood is such that there is no sound proofing from the engine noise, it just comes up through all the gaps. The van itself magnifies the deep Diesel thud.

This is the main reason why a modern diesel engine transplant isn't a good idea. A modern Diesel engine is not that much quieter than of old, it is just isolated up front behind a thick insulated Firewall. They also have a 'top' engine cover that sits on the engine itself and absorbs a lot of noise. Without the engine top cover and the missing insulation (no room in a H van engine bay) having a modern diesel in the Cab with you will drive you nuts.

The Petrol engines are strong, particularly the early cast Iron head engines from about 1954 - 1963, the later Aluminium Head engines are prone to Head Gasket failure, particularly so if the engine is worked hard, like on a big Catering conversion, after a period of hibernation. This is not a weakness in the engine but purely down to the life of the gasket material which wasn't designed to last 20 years let alone 40.

If the Head Gasket does fail, it is essential it is done correctly, otherewise you will have repeat symptoms of Head Gasket failure, Water in the Oil.

Replacing the Head Gasket properly, stripping and rebuilding the Cylinder Head with a light skim, removing the liners, etc is 3/4 on the way to a full engine rebuild and usually more cost effective to have an exchange engine with new Clutch. It will save a whole load of expense in the long term as all the old gaskets will be in their twilight years. A gasket has a design life of about 20years, so an engine that is 40 + years old will start leaking Oil and giving issues in lots of areas.

We have recently had 4 vans in for replacement engines, all of them the later Alloy Head engine. Three of them had another Garage replace the Head Gasket in the previous 6 months, but it had failed again. Each owner thought that going to their local Garage was the most Cost Effective option, but doing so put them out of pocket to the tune of up to £900. One was off the road for 2 months while the Garage tried to find the parts.

These engines are not Rocket Science, but they do have thier little quirks, and if not done correctly will fail again.

They are strong, but there are weaknesses that can be addressed at a full engine rebuild that will save catastrophy later. For example the Timing Chain is prone to failure, when it goes it can cause major damage. If you have any significant work done to the engine get the timing chain replaced as well.

LPG converted petrol engines are often sweeter smelling and quieter on gas, which in a Citroen HY is a bigger bonus than most vehicles!!. The general concensus is that if you want to convert to LPG then the Cylinder head should be machined accordingly.

If you can find a good petrol HY that is already converted to LPG it will be worth another £1,500 as the pay back in servicing and fuel savings will be recouped in less than 2 years, even at low annual mileages.

In good condition these engines use oil, around 1.0 litre every 1,000 miles is typical. However, when these engines age they consume (and leak) litres of Oil. The Valve guide oil seals harden with age and the Cylinder Bores wear leading to an Engine Oil bill that can be as much as the fuel bill!! The smell from the Oil burning in the exhaust becomes quit unpleasant.

These engines will start and run even in very poor condition, but If the engine continues to be used in this state it is likely to fail catastrophically, so unlikely to be repairable, leading to a bill of £3,000 - £4,000 for a replacement. For example a new crankshaft will almost certainly be required, these cost over £1,100.

If the engine in the van you are buying is in a bad way, budget around £2,000 for a rebuild STRAIGHTAWAY as it will save money in the long term.

GEARBOX

The Gearbox, is a simple 3 speed design that is very strong but not having syncromesh on first is a real handicap on todays roads.

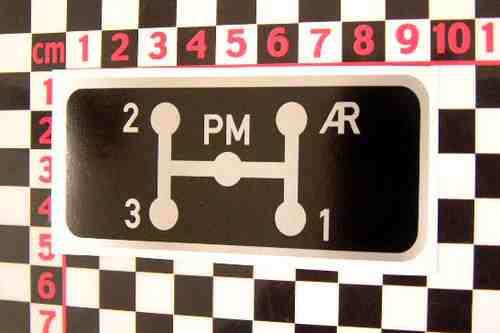

Note the unusual shift pattern on the below photo for the later post 1963 vehicles :

Print the picture and stick it to your dash board, I was surprised how quickly I got used to it.

However be aware that there are two types of Gearshift mechanism, one of which reverses the Gear change pattern so the above might apply in the exact opposite direction? The nicer, change mechanism (this is in the van itself and not part of the Gearbox) seems to be fitted to pre 1961 vans.

From 1961 the gearchange has an unusual sideways sliding action which will strain the lever causing the lever to break off in your hand if you try and move between the gate with a conventional 'tilt' action. The way to change gear in a post 1963 H van is to apply a 'little lift' to almost raise the lever as you move it sideways to the right.

Synchromesh on 2nd is a common failing. There is no synchromesh on 1st so it is best to only select this gear if you are stationary, unless you double de-clutch. Likewise the input shaft Sealusually needs replacement. It is not uncommon for both the upper and lower rear bearings to wear, causing the retaining nuts to loosen at the back of the box, eventually wrecking all shaft bearings and sometimes gears if not addressed quickly. The Crown wheel and/or Pinion are often damaged and the Pinion shaft bearing sometimes fails. This is no longer available. Rebuilding the box requires special tools to dismantle the Gearbox and a lathe to make up spacers.

Our advice would be that unless the gearbox is absolutely perfect get it rebuilt as soon as it shows ANY sign of trouble because it will be cheaper than if you wait until it breaks.

Budget about £1,800 to rebuild a gearbox but if the Crown wheel and/or Pinion are damaged add another £600.

Unless it has been done expect the Clutch to require renewing. There are 2 basic types of Friction Disc which are easily established via the bellhousing inspection cover. The early type Clutch Disc is not interchangable with the later type Flywheel. The Clutch cover is the same for Indenor Diesel, Petrol Type H up to about 1967. Later Petrol engines had a better Clutch 'spring' Disc and Cover that reduce judder.

If the Clutch thrust/Release Bearing is worn, it will eventually wreck the Clutch Pressure Cover. Cost of a new Clutch is £100 for the Thrust/Release Bearing, £67 for a Clutch Disc/Plate and around £150 for the Clutch Pressure Cover. Add on about £800 labour.

Before you buy any van get someone to check the wear on the Release Bearing

BRAKES

You might read a lot about "The Brakes" but if rebuilt properly the later vans can be perfectly usable on modern roads.

The bad reputation is often based upon poor adjustment, old tired brake shoes and pre 1963 Drums which were narrower and had only 19mm rear slave cylinders.

It makes a huge difference if the brakes are set-up correctly (which needs to be done every 3,000 kms) Post 1964 brakes, if set up correctly with our High Friction non Asbestos brake shoe linings, are actually very good. 1968 onwards are even better

The Brakes are not self adjusting, they need manual adjustment every 3,000 km when a full service should also be done.

When they need major work the cost is nothing like a modern van, it can be up to £1,600 to totally overhaul an H van brakes. Very time consuming if done right. It is because of the complexity, time and cost that the Brakes are rarely looked after. Expect them to need major work very rarely are they right.

A van that came into the workshop in August 2015 had trouble being pushed off the transporter because the brakes were seized on. Yet the new owner had paid a Southeast specialist H van trader, from whom he had bought the van, £2500 to overhaul the brakes only a few weeks before. The rear Slave Cylinders had been replaced with the wrong size, and the fronts leaking and seized.

Nor had the handbrake cables been replaced, most likely because of the £120 cost. The Master Cylinder was new as were some Brake pipes. One very old front flexi hose was split (not cracked, but actual so tired it was split) yet the two rear flexi hoses were new. Very dangerous.

STEERING

Steering Column top bush wears quickly because of the forces it has to take when manouvering the unassisted steering wheel. But it is cheap to fix.

The steering rack will probably have tired rubber gaiters, which requires the rack to be removed to fit new ones. You can buy leather gaiters but they are not as oil/dust proof as they should be, but they can be 'sewn' on with the rack in place. If you have the leather gaiters fitted they should be removed each year to be have the contaminated grease cleaned out and new Grease injected. We would recommend you avoid these as they a prone to 'bunching up' and restricting the Steering.

If a van has been restored properly it will have Rubber Bellows style Gaiters as the restorer would have removed the Rack to rebuild it and fitting new rubber gaiters is then only a 10 minute job if the Steering Rack is already removed. If the Van has Leather 'wrap around' gaiters you can be pretty safe betting it has not been rebuilt.

SUSPENSION

Front suspension has a number of joints/bushes and is very robust, almost every joint has a Grease nipple and is adjustable to take out play.

If greased correctly/regularly it will last a long time. Unfortunately the Grease nipples often don't get attention during maintenance so the joints suffer as a result. Get them Greased as a bottom Ball Joint is over 120euros. Track rod ends are a common wear point but not hard to replace/rebuild. They are sometimes diagnosed by non specialist Garages as the reason for Steering play, when the culprit is often the Lower balljoint.

The rear Torsion bar suspension also appears to be quite robust. but watch out for worn Radius Arm Bearings that can be time consuming to replace. The Oil Seal surface on the Radius Arm is prone to severe wear letting in water and dirt. This must be resurfaced when replacing a Bearing otherwise the new Bearing will fail in months.

We can supply rebuilt Rear Suspension Radius Arms.

Budget for new shock absorbers, 2 on the back and four on the front upto 1969. Just two shock absorbers on the front after 1969.

Rears shocks cost around £180 a pair and the original type must be used when they lay horizontal with the Valves located correctly. Conventional modern upright Shocks must not be used as these usually have a valve at the top.

TYRES

Check the tyres very carefully. you are looking for a wrong size having being fitted. Many 'estorers' are fitting the wrong size, cheaper tyres.

When the van was first made there were 2 metric tyre sizes 17r400 and 19r400. The17r400 has a smaller diameter and it affects the gearing dropping the top speed by as much as 5mph on some vans. Production of the 19r400 stopped about 10years ago. Vredestein recently did a small production run of the small 17r400 tyres and there is still some stock left at £239 a tyre. 19r400 tyres are now very sought after, but even the youngest will be about 10 years old.

Many vans we have seen have had the wrong tyre fitted affecting the Gearing and leading to very low top speeds, sometimes only 40mph!!

See our TYRES page for info on alternative tyres and sizes costing as little as £59ea.

Transport of your Purchase

If you do decide to buy one and need to trailer/transport it, you should be certain of it's weight. While transporting an empty standard van is perfectly feasible, as it only weighs about 1,400kg. Transporting a Catering conversion will most likely bring you into contention with the Law as some Catering H vans are close on 3,000kg.

There is not currently a Tow Car/4x4/SUV/Pickup that can legally tow such a vehicle as the weight of the Van + Trailer exceeds that of even the mightyMitsubishi Shogun Tow vehicle. Please read our Weights and Towing section on the HY Dimensions page for more information.

Trailering a heavy H van can incur hefty penalties. The Police are aware that many Catering vans are over the limit and make them a target. Read my own unpleasant experience when stopped by the Police/VOSA when Trailering a H van.

Likewise Driving an overloaded H van carries big penalties. The fully loaded weight of the van, including Drinks cans, Burgers, serviettes, Water, Fuel, driver/passenger, Stock, etc must be less than the Weight plate on the side of the vehicle. On the bigger vans it is 2900kg, on the HZ's it can be 2200kg.

One customer claimed his van only weighed about 1700kg which we questioned when we had to raise it on a 2 ton trolley jack.

He then had it weighed to find it was actually 2670kg empty. The fuel tank was almost empty so another 35kg for Fuel, 170kg for Driver/passenger so 2800kg before the water, stock, Drinks cans, etc.

We have seen vans with a weight plate of 2,990kg which we believe have been over 3,600kg because of all the heavy Stainless Steel and Catering equipment.

A fully kitted Catering H van can be a lot heavier than most people think. A Trader Driving it when in a Dangerous, overloaded state can get a Ban and hefty fines. The Police know H vans are drivenover the limits a lot of the time and make them a target. I was stopped and weighed but was legal so no Points, Fine or Ban, just a horrible 12 hour delay on my journey.

'Because of the width of the HY track and the narrowness of most trailer beds it is tricky to drive your HY onto the trailer.

See this example of how NOT to load an H van onto a Trailer : -http://www.youtube.com/watch?v=DjhwJjDlmPs